|

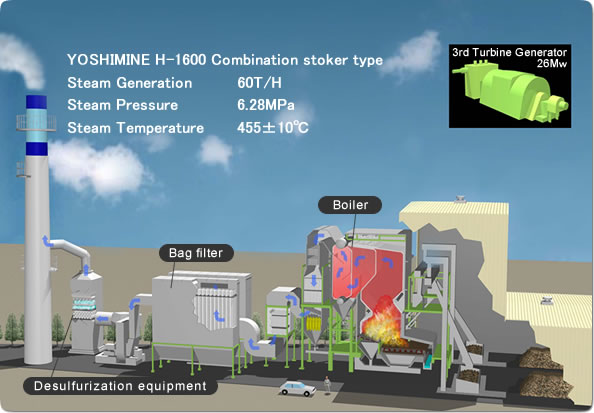

Business and Technology : POWER GENERATION BOILER FIRING MIXTURE OF SLUDGE (FROM PAPER MILL) AND WOOD CHIP

|

We have succeeded in development of the boiler for power generation by combination burning of Sludge from a domestic paper mill and Wood chip. The sludge is a fuel with high moisture and ash, which is difficult to burn in the convectional stokers. But we have developed a boiler to burn well with sludge and wood chip combined by employing the specially designed stoker system to the full satisfaction of the customer's requirements.

BOILER SPECIFICATION & OPERATION DATA CHART

| BOILER TYPE |

Bi-Drum Natural Circulation type YOSHIMINE H-1600 Type |

| COMBUSTION SYSTEM |

Pneumatic spread type Combination stoker |

| FUEL |

- Paper Sludge

- 5,00〜6.00 MJ/kg(LHV)

- Wood chip

- 13.20 MJ/kg(LHV)

- C-Oil

- 41.13 MJ/kg(LHV)

|

| STEAM GENERATION |

60 t/h |

| STEAM PRESSURE |

6.28 MPaG |

| STEAM TEMPERATURE |

455 ±10 ゜C |

| ITEMS |

UNIT |

DESIGN |

ACTUAL |

| BOILER EFFICIENCY |

% |

83 |

85 |

| UNBURNT COMBUSTIBLE CONTENT OF MAIN ASH

|

% |

3> |

2.3 |

| NOx |

ppm |

90> |

82 |

| SOx |

ppm |

10> |

4.1 |

| PARTICULATE |

g/Nm³ |

0.04> |

0.01 |

| DIOXIN CONCENTRATION |

ng-TEQ/Nm³ |

0.1> |

0.015 |

The facility's operation is controlled by DCS installed in the Central Control Room. Fuel is pneumatically supplied by controlling the flow each according to the sludge and wood chip systems. In order to prevent pollution, NOx removal equipment (using urea) is installed in the combustion chamber to remove NOx,mechanical dust collector and bag filter (blowing in slaked lime and activated carbon) are installed to removed dust or particles and Dioxin respectively, Desulfurizer (using caustic soda) is installed to remove SOx, Mist separator is installed on the top of chimney.

BIRDS-EYE VIEW OF FACILITY